Author: Zia Abdullah, Laboratory Program Manager, National Renewable Energy Laboratory

Read Zia's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

Supported by the U.S. Department of Energy Bioenergy Technologies Office, the National Renewable Energy Laboratory is striving to bring more low- and zero-net-carbon sustainable aviation fuel to the market.

The equivalent of 30,000 Olympic-sized swimming pools—that’s how much jet fuel the United States consumes in a typical year.

According to the U.S. Energy Information Administration, U.S. airline carriers consumed over 20 billion gallons of petroleum-based jet fuel in 2019. With a growing population and increasing demand for goods from around the world, that volume is projected to grow over the next several decades.

So, when we talk about decarbonizing the aviation sector, increasing supplies of sustainable aviation fuel (SAF) is often at the center of the discussion.

Why Sustainable Aviation Fuel?

SAF is a highly polished hydrocarbon fuel with precise properties to enable safe, reliable flight, but with a fraction of the carbon footprint.

Because SAF is made from a wide range of renewable biomass and waste resource, the fuel can net deep reductions in greenhouse gas (GHG) emissions. For example, SAF made from wet waste—a low-cost resource that includes food waste, animal manure, and sewage sludge—can have a carbon footprint some 165% smaller than petroleum-based jet fuel by keeping waste from rotting and releasing methane and CO2 emissions in a landfill.

This makes SAF an effective technical solution for drawing down aviation GHGs. The Biden-Harris Administration has set bold but achievable goals to increase SAF production to at least 3 billion gallons per year by 2030. It aims even higher in the long run: 35 billion gallons by mid-century, enough to cover 100% of projected aviation demand.

With big fuel volumes at play and a growing urgency to comprehensively tackle the climate crisis, a robust research strategy is essential for meeting these goals.

Supported by the U.S. Department of Energy’s Bioenergy Technologies Office, the National Renewable Energy Laboratory (NREL) is advancing three key strategies to accelerate the production of climate friendly jet fuel.

Strategy 1: Rapidly Develop and Scale Biorefining Processes for Making Drop-In, Net-Zero-Emission SAF

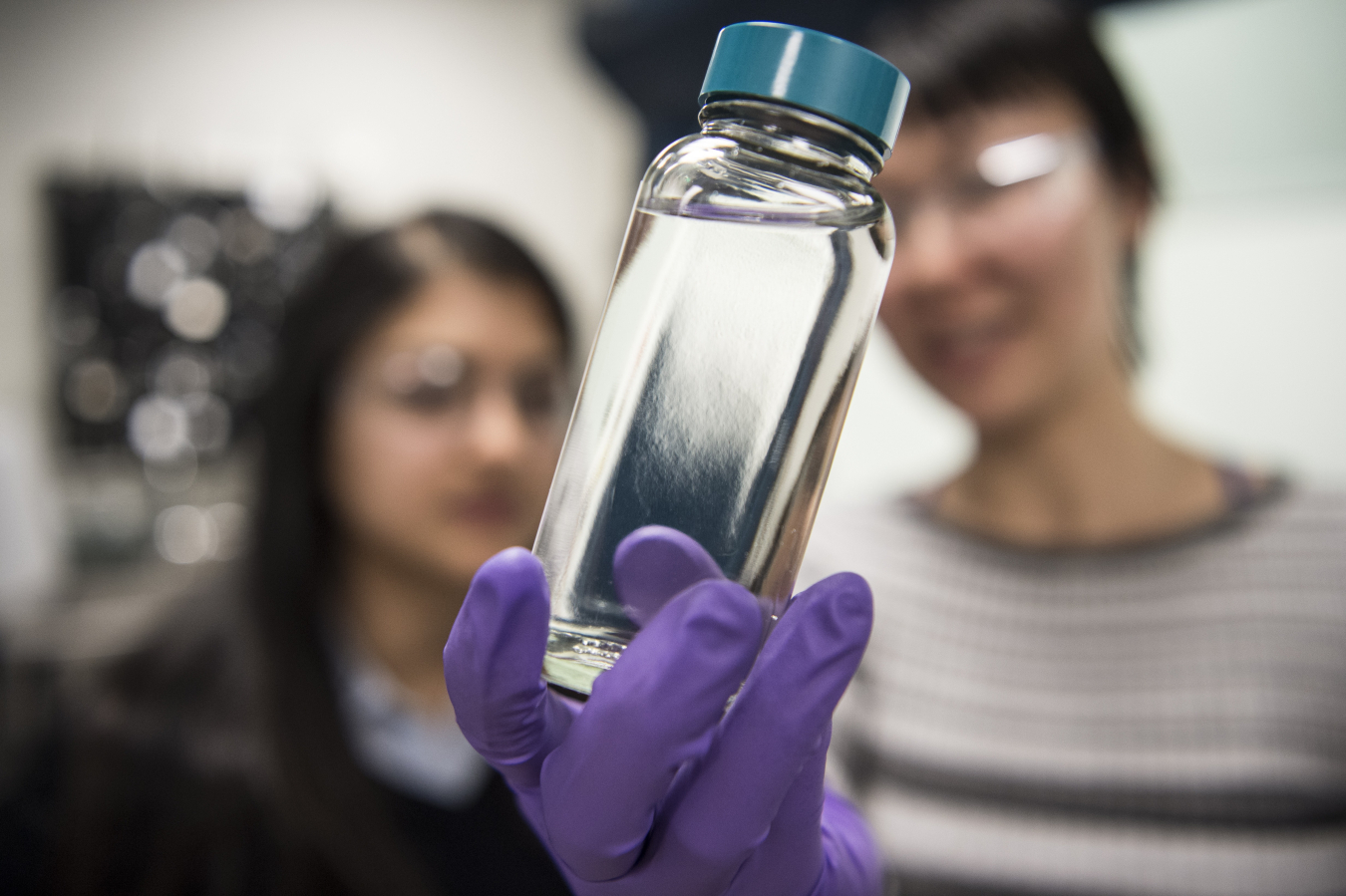

NREL researchers examine a container containing a “drop-in” biofuel synthesized at NREL. Image courtesy of Dennis Schroeder, NREL

Fuel refiners must cover a lot of ground to scale SAF production to 3 billion gallons in less than a decade. Airlines only consumed an estimated 2.4 million gallons of the low-carbon fuel in 2019. To close the gap, the industry must grow supplies by nearly 1,200 times.

NREL and its industry partners use applied science to turn that rigorous timeline into an achievable milestone. At the center of this work are net-zero-emission biofuels designed to be 100% compatible with existing aircraft.

Known as “drop-in” fuels by the industry, these SAFs are chemically very similar to conventional jet fuel. They can be used in the same pipelines, the same storage tanks, and the same engines as today’s fuels. This allows airlines to seamlessly integrate the fuel with current operations and infrastructure—no costly delays required.

NREL scientists and analysts are inventing new production pathways to meet demand for drop-in SAFs:

- Characterizing and taking stock of the nation’s potential 1 billion tons of biomass and waste resources— “fuel feedstocks” that can be sustainably harvested each year to make biofuel

- Developing and demonstrating highly efficient, stable, and cost-effective refining processes for transforming those resources into highly polished fuel

- Analyzing the economic and environmental impact of making large amounts of SAF at scale.

For U.S. airlines, these efforts translate into blueprints for realizing fast, quantifiable drops in net GHG emissions in as little as a few years.

Strategy 2: Design Resilient Biorefineries That Can Flex With Changing Feedstock Supplies

NREL engineers run product samples though NREL’s customizable Davison Circulating Riser reactor system. Image courtesy of Dennis Schroeder, NREL

Steep price tags for new SAF infrastructure can discourage biofuel refiners looking to enter the market. And although ample domestic resources can translate into economic opportunity, diverse fuel feedstocks can also complicate refining processes.

After all, it’s not easy to transform corn stover and sewage sludge into the same, zero-emission SAF using the same equipment and process.

NREL offers refineries solutions for overcoming these challenges. With the laboratory’s cutting-edge pilot plants, scientists deeply analyze, trouble shoot, and tune SAF refining processes to sidestep complications by design.

NREL researchers demonstrate SAF processes in real time, revealing how to “bolt” them onto existing production facilities, making it easier for companies to integrate the technology. For example, a recent NREL study demonstrates how to co-process bio-oils with petroleum at existing refineries. Such an achievement offers an accelerated pathway for producing more climate friendly SAF without waiting for new facilities to come online.

Whether it’s a SAF startup like Alder Energy or a refinery catalyst giant like Johnson Matthey, NREL is providing companies the insights they need to ramp up SAF production.

Strategy 3: Build Strong, Diverse Coalitions

An NREL scientist discusses sustainable aviation fuel with Kelly Speakes-Backman, Principal Deputy Assistant Secretary of DOE’s Office of Energy Efficiency and Renewable Energy. Image courtesy of Werner Slocum, NREL

Smart technical solutions are essential for accelerating SAF production, but perhaps the most valuable strategy starts outside the lab with partnerships.

We need diverse coalitions of experts, companies, agencies, and perspectives to accelerate the deployment of SAF:

- Cross-Lab Coalitions. Research consortia pool expertise from across the DOE lab system to give answers to the most pressing technical and analytical questions for achieving U.S. aviation goals. The Chemical Catalysis for Bioenergy Consortium, for example, recruits more than 120 researchers from eight DOE national labs to accelerate the development of catalytic technologies essential for making SAF from biomass and waste.

- Cross-Agency Coalitions. Through the SAF Grand Challenge, federal agencies share the resources and information needed to lower aviation emissions 20% by 2030. Energized by national lab analysis and technologies, this cross-agency investment promises to transform the aviation sector, while supporting the economy, boosting American agriculture and manufacturing, and addressing the climate crisis.

- Cross-Industry Coalitions. Funding from the DOE Bioenergy Technologies Office mobilizes fuel refiners and aviation companies to demonstrate SAF technologies at large scale. Pairing industry ambitions with DOE experts, these resources help build momentum and scale, helping lower production costs across the SAF supply chain.

Our Future Is Fueled With SAF

In the United States, aviation accounts for 9%–12% of total greenhouse gas emissions from transportation. Although that percentage is only a small slice of the bigger emissions pie, reducing aviation emissions rapidly is essential to match the urgency of the climate crisis.

By pursuing targeted strategies to accelerate the production of SAF, NREL and partners are putting a new notch in aviation history by decarbonizing flight. But the benefits needn’t stop with lower emissions.

A future fueled with SAF could unlock additional social, environmental, economic benefits—from creating jobs to restoring soil and watersheds to improving aircraft performance.